Why do concrete element joint seals need to be flexible?

Concrete element joint seals have many important functions. Joint seal has to accommodate to the constant movement of the element. Moisture entering inside a building through broken joint seals cause, e.g., a mold that is harmful to the construction and the people living in it. Joint seals need to keep water, air pollution and noise out of the rooms, and costly cooled or warmed air inside an apartment.

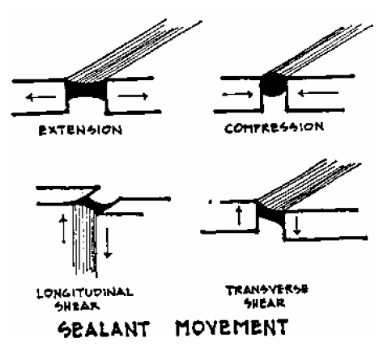

The basic thing is that the joint sealants of concrete elements need to be flexible. It is not a durable solution to put inflexible plaster between concrete elements. The inflexible material will not last for long in the joint because of the inevitable movement of the concrete elements. Unavoidable reasons for joint movements are concrete element fading, thermal motions, seismic movements and the wind.

In order to choose the most cost-effective and endurable sealant, we need to know a lot of things. We have to study the stretching and compression of the joint in that special case and estimate how much, for instance, moisture and UV-radiation resistance is needed. Moreover, there are different sealants and working methods for, e.g., skyscrapers, water treatment plants, dumping grounds, and window and door perimeters. Fire retention issues of sealants need to be taken into account as well.

Thereby, high-quality joint sealing requires a broad understanding of different sealants and astonishingly many different skills and the know-how of the right working methods. In practice, joint sealing work consists of many phases, and all of them need to be done in a right way. The joint sealer must also know, e.g., when and how to fix broken concrete elements and rusted element reinforcements as well. There is not much value of a good joint seal if the element leaks next to the joint.

Solutions to the problems of concrete element joint sealing are worth to look for in Finland. Finland is a forerunner in concrete element construction and joint sealing in the world since the 60’s. Rude Nordic climate has made Finland a testing laboratory for concrete element joint sealants as well. In winter it is often almost minus 30 degrees Celsius and in summer almost plus 30 degrees Celsius. Because of that much of thermal motion, joint seals of concrete elements must withstand especially hard stretching and compression. In addition to this, there many special and very demanding concrete element constructions in Finland that are extremely challenging for flexible joint sealants.

The most profound know-how of concrete element joint sealing is to be found In Saumalaakso Ltd. It is a leading company in Finland, founded in 1986, in concrete element joint sealing and solving related problems. Solutions have been developed based on a long experience and disciplined product development together with material producers, universities and professional institutes.

The selection of the right sealant in different situations is very important. A well done joint sealing with suitable sealant may last 10 to 25 years. In many cases, the inflexible sealant will be broken at once. The most common sealants are polyurethanes, silicones, hybrids, acrylic, polysulfides, butyls and latex. They differ in qualities in many ways. A new solution is impregnated joint sealing tapes, which can be installed in the concrete element joint in almost any circumstances. Other sealants will not last in the joint if they are installed in too cold, hot or wet conditions. All of these sealants have pros and cons.